Dongguan QiMao Electronics Co., Ltd.

Dongguan Xunyao Electronic Technology Co., Ltd.

Dongguan Huajun Electronics Co., Ltd.

+86 0769-82116029

+86 139-2250-7529

+86 0769-82116029

+86 139-2250-7529

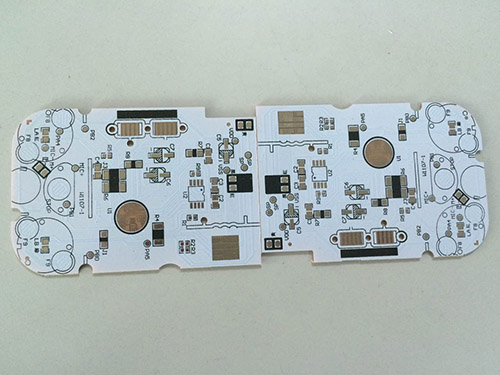

Line layer

The circuit layer (generally using electrolytic copper foil) is etched to form a printed circuit for assembly and connection of devices. Compared with the traditional FR-4, with the same thickness and the same line width, the aluminum substrate can carry higher current.

Insulating layer

The insulating layer is the core technology of the aluminum substrate, which mainly plays the functions of bonding, insulation and heat conduction. The aluminum base insulation layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of heat generated during the operation of the device, and the more conducive to reducing the operating temperature of the device, so as to achieve the purpose of increasing the power load of the module, reducing the volume, prolonging the life, and improving the power output. .

Metal base layer

Which metal is used for the insulating metal substrate depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

Generally speaking, considering the conditions of cost and technical performance, aluminum plate is an ideal choice. The optional aluminum plates are 6061, 5052, 1060 and so on. If there are requirements for higher thermal conductivity, mechanical properties, electrical properties and other special properties, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

About Us

Company Profile Production Strength Honor Partner PCB circuit boardTechnical Support

Cooperation StrengthProcess CapabilityProcess explanationNews Center

NewsIndustry InformationCommon ProblemContact Us

Contact Online Message1-4th Floor, Back Building, No. 305 Zhenxing Avenue, Taiyuan Community, Xiegang Town, Dongguan City

Tel: +86 0769-82116029/82116039

Contact: +86 13922507529/Mr. Huang