Dongguan QiMao Electronics Co., Ltd.

Dongguan Xunyao Electronic Technology Co., Ltd.

Dongguan Huajun Electronics Co., Ltd.

+86 0769-82116029

+86 139-2250-7529

+86 0769-82116029

+86 139-2250-7529

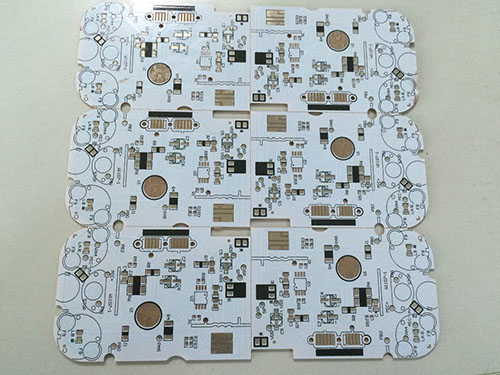

Since the birth of LED, the problem of heat dissipation has always been a major problem for manufacturers. If the junction temperature of the LED exceeds 85 degrees, it will lead to chip failure, phosphor oxidation, and light decay. The heat dissipation performance directly affects the life of the LED lamp. The aluminum substrate has the characteristics of high thermal conductivity, low thermal resistance, withstand voltage, light weight, and anti-oxidation. The advent of the LED aluminum substrate has brought a new solution to the heat dissipation problem of the product.

The double-sided aluminum substrate is composed of a three-layer structure of a circuit layer (copper foil), a thermally conductive insulating layer and a metal base layer. Its working principle is that the surface of the power device is mounted on the circuit layer, and the heat generated during the operation of the device is quickly transferred to the metal through the insulating layer. The base layer, and then the heat is transferred out by the metal base layer, so as to realize the heat dissipation of the device. Aluminum substrates are widely used in the LED industry, including LED street lights, spot lights, Xian wall lights, buried lights, LED fluorescent lights, etc. In 1969, a Japanese company first invented the aluminum substrate manufacturing technology, and in 1974, it was applied to the STK series power amplifier hybrid integrated circuit. The research and development of aluminum-based copper clad laminates in my country began in 1988. The state-owned factory completed the factory-level design and finalization of general-purpose aluminum substrates in 1990, and established the first domestic aluminum-based copper clad laminate production line and put it into production.

The quality of the aluminum substrate directly affects the quality of the finished LED lamps. Due to the low entry threshold, lack of core technology and imperfect industry standards, the current domestic aluminum substrate market has a phenomenon of mixed product quality and mixed fish. There is no specific measurement specification for the thermal conductivity of aluminum substrates. The thermal conductivity of aluminum-based copper clad laminates produced by different manufacturers is quite different. The quality of products produced by some aluminum substrate companies is difficult to guarantee, and the measured data of thermal conductivity does not match the nominal data. At present, there is a certain gap between the domestic aluminum substrate technology level and the international level, lacking the support of core technology, the products are generally low-end homogeneity, the products with low price and low quality occupy the market, and there are very few high-end products. Enterprises form vicious competition in price wars, and price pressure leads to meager profits in the entire industry.

Aluminum substrate is the mainstream product of heat dissipation substrate. The government and relevant industry departments need to pay more attention to the aluminum substrate industry and strengthen the formulation of industry standards, testing and certification systems. Enterprises should be based on the long-term lighting market, establish brand awareness, and align with the advanced level of the industry in terms of product technology.

About Us

Company Profile Production Strength Honor Partner PCB circuit boardTechnical Support

Cooperation StrengthProcess CapabilityProcess explanationNews Center

NewsIndustry InformationCommon ProblemContact Us

Contact Online Message1-4th Floor, Back Building, No. 305 Zhenxing Avenue, Taiyuan Community, Xiegang Town, Dongguan City

Tel: +86 0769-82116029/82116039

Contact: +86 13922507529/Mr. Huang